Covestro will showcase new polyurethane (PU) coating systems and films at this year’s Techtextil trade show in Frankfurt, Germany, that are more sustainable and environmentally compatible in terms of raw materials, processing, and properties. “For example, we will be presenting new PU dispersions as binders for digital textile printing and a new two-component (2K) PU high solid system of our INSQIN® technology for textile coating,” explains Thomas Michaelis, Head of Textile Coating in the Europe, Middle East, Africa and Latin America (EMLA) region at Covestro. In addition, Covestro’s booth will focus on variants of Dureflex® TPU films, which are skin-compatible and guaranteed free of harmful substances according to the OEKO-TEX® Standard 100.

Good haptics and durability with high color intensity

Digital textile printing enables economical production of small batches, shortens time-to-market, and reduces waste volumes by up to 85 percent compared to analog printing technologies. PU dispersions are currently establishing themselves in the production of inks for digital inkjet printing processes because, among other things, they enable a stable printing process due to their low viscosity and particle size. With Impranil® DL 1602, Covestro is launching a new anionic, aliphatic-based PU dispersion that can be used to formulate water-based pigment inks for digital inkjet printing. The dispersions show excellent stability at high shear rates. They produce very finely divided ink dispersions with good jetting behavior that are characterized by high re-solubility. “This minimizes the risk of the pressure nozzles becoming clogged. Long and therefore economical runtimes in printing are the result,” explains Dr. Inga Bargende, Digital Printing Expert at Covestro. Other strengths of PU-based inks include good abrasion and rub resistance and high color and wash fastness.

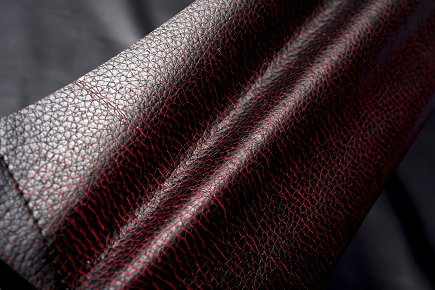

Long pot life and high grain stability

The new INSQIN® 2K PU system consists of Impranil® HS 1062 and Imprafix® IO 3330. It mainly targets synthetics for car interiors. The High Solid system does not require blocking agents. “Nevertheless, it is characterized by long pot lives during processing. This means, for example, that the processor does not necessarily have to use PU mixing heads. It also gives the grain a high degree of stability and is particularly resistant to hydrolysis,” explains Michaelis. Potential applications include instrument panels, seats, door panels, or steering wheels.

Certificate for TPU films free of harmful substances

Several TPU (thermoplastic polyurethane) films in Covestro’s Dureflex® product line have now been certified to the 100 by OEKO-TEX® standard. The films are breathable, waterproof, tear-resistant and, above all, kind to one’s skin. That makes them the material of choice for sports articles and outdoor clothing, but also for furniture and seat covers for cars. In 2019, several Platilon® brand TPU film grades have already been certified to the standard.

Covestro will also be showcasing its partially biobased Platilon® H2 EC hotmelt film at Techtextil. “It exhibits excellent adhesion during lamination, is very heat resistant and easy to process. Applications include textile labels, sealing strips, laminates made of glass and aluminum, and conductive tracks for the textile and automotive industries,” explains Dr. Elmar Lins, Segment Manager Consumer & Industrial Solutions Specialty Films for the EMLA region.

Techtextil will be held at Messe Frankfurt from June 21st to 24th, 2022. Covestro’s booth in Hall 11 is number D12.