Hyderabad, August 2022: Global Aluminium’s saga started way back in 1996, when a visionary Mr. Anil Kumar Agarwal, envisioned the vital role of aluminium in the world metal industry for the coming years and the way it would transform different industries across India and the world. Today as Global Aluminium completes 25 years of its successful journey, it is India’s largest exporter of value-added aluminium extrusion profiles and also the emerging market leader in aluminium extrusion manufacturing, which serves over twenty thousand customers across the globe.

Global Aluminium had a small beginning with a commitment to produce excellent quality aluminium extrusion profiles from one extrusion press and assumed the modern form within a decade, to become the one of the largest aluminium extrusion manufacturing company in India and the most sought-after partner for global aluminum business requirements.

While many manufacturers have been trying to force push the pre-set extrusion profiles to customers during early days, Global Aluminium disrupted the environment with technologically advanced presses, facing the evolutionary challenges with ease, which till then were thought it was impossible to make custom-made products, in various shapes basis customer design requirements. By 2005, Global Aluminium managed to attain 5 aluminium extrusion presses with a capacity of 20,000 Metric Tonnes per annum.

Later in 2005, with the increased capacity & production, Global Aluminium started servicing the clients from across the globe among different industries, eliminating the trade boundaries between countries and that was our year of exports. With cues from global and domestic markets on financial crisis, our visionary leader strategically managed the situation and in turn made it into an opportunity to access the creativity and skills in the market. However, no crisis stopped it from growing and expanding, accomplished 4 new extrusion presses including large tonnage presses with higher billet dias. Understanding the importance of value addition, priorities had been revisited in 2011-12 diversifying into value addition technologies for aluminium such as anodizing and powder coating, thereby becoming the third largest aluminium extrusion manufacturer in India with highest number of presses under single roof.

With continuous improvements in terms of technology and strategy, Global Aluminium missed no opportunity to transform itself into a new-age aluminium extrusion manufacturing company, accessing and developing right skills at right time, became India’s most renowned aluminium extruder for quality & reliability. Amidst innovations and collaborations, starting from 2016, they have expanded every year with machining operations plus fabrication, then set up ageing and oven foundries in 2018 and became largest value added aluminium extruder by 2021.

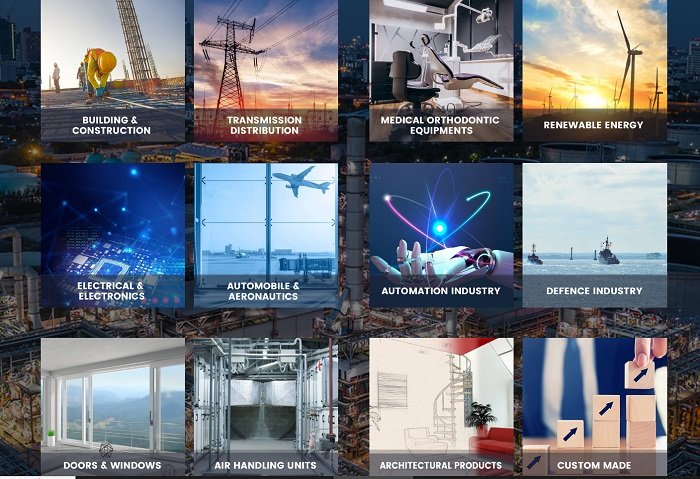

While Global Aluminium have achieved fast paced growth over years, they have also attained to build over 25000+ different profiles and more than 50,000 dies, with a capacity of 50,000 MT per annum. Today, GAPL is serving 20,000+ businesses across globe from segments such as Building & Construction, Architectural, Automotive & Aeronautics, Defense, Medical equipment, Automation and more.